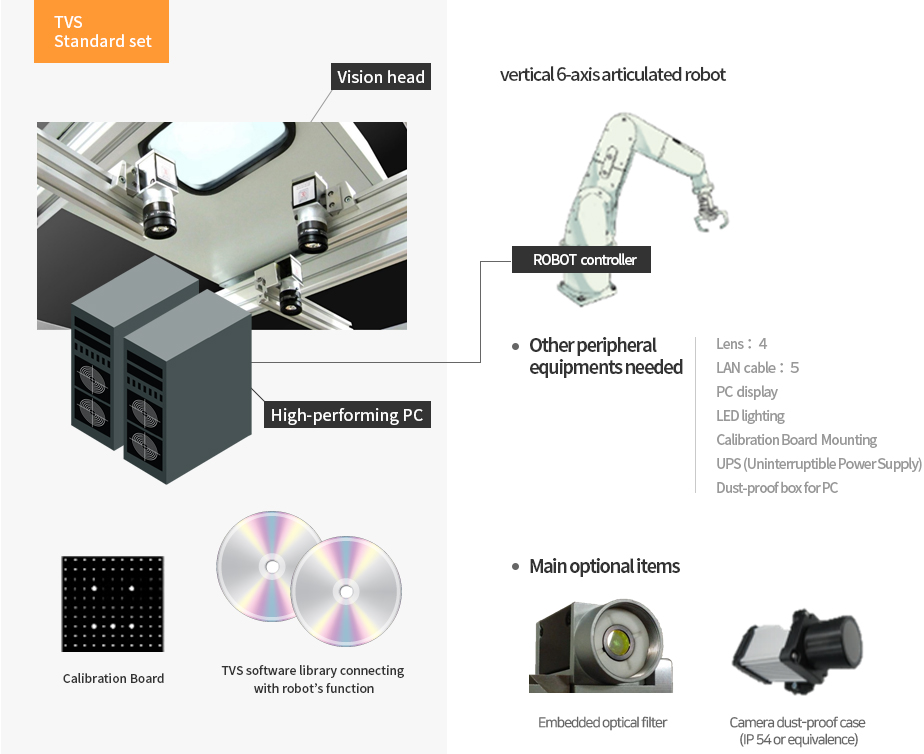

INTRODUCTION OF PRODUCTS

Our company RAMS strives to realize new technology development,

customer satisfaction and respect for humankind.

Our company RAMS strives to realize new technology development, customer satisfaction and respect for humankind.

| Project | Contents | ||

|---|---|---|---|

| Common Spec. | Accuracy (※1) | 1/2000-level Vision ~ | |

| Recognition time (※1) | 1.6 sec ~ | ||

| Product CAD data format | STL format | ||

| Vision head part protection grade | IP 54 or equivalence | ||

| Robot manufacturers compatible with RAMS library | Kawasaki, Denso, Wave, Fanuc, Fujokoshi, Mitsubishi, Yasukawa, ABB (Compatible controller and other options available upon request) |

||

| V | AC 100 / 110 ± 10% | ||

| W | 900 | ||

| Individual Spec. per Field of Vision |

Operation environment | [℃] Temp. | 10 ~ 35 |

| Humidity [%] | 20~80 (Without dew condensation) | ||

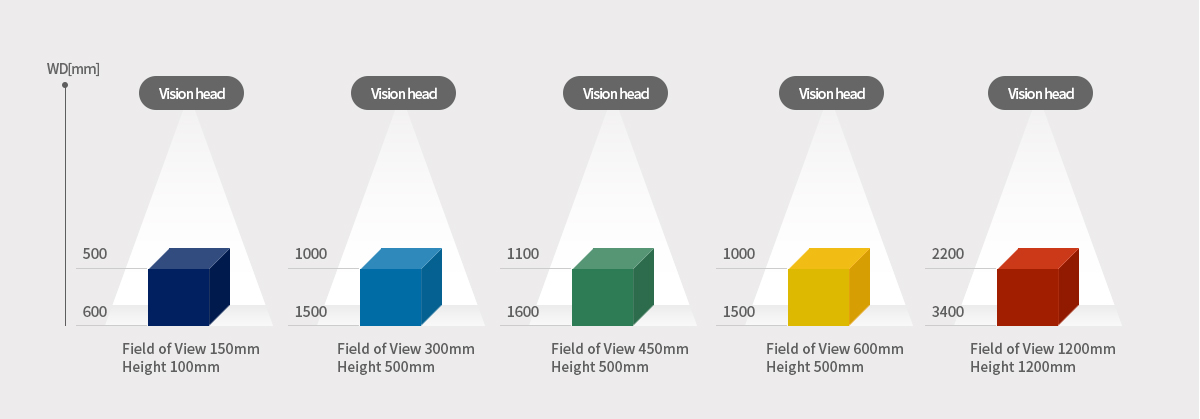

| Field of vision 150mm | WD [mm] (※2) | 500 ~ 600 | |

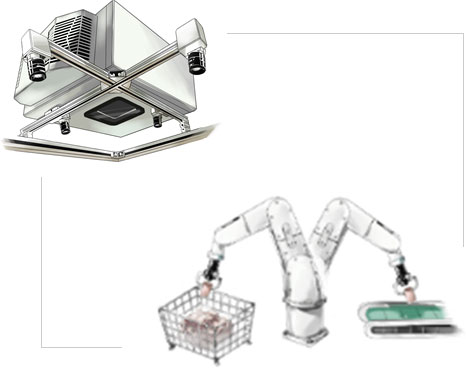

Realizing automation of bulk parts supply,

via high-speed and precision recognition

level

Passion and technological competence. The fruit of the workplace know-how.

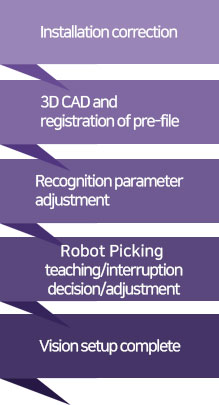

Line application examples

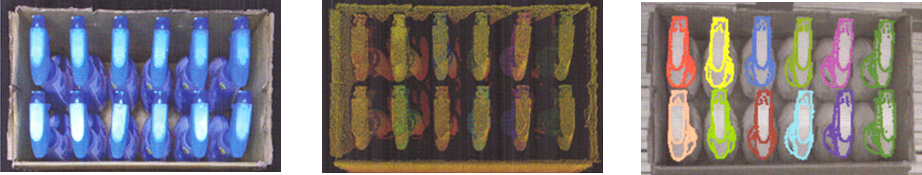

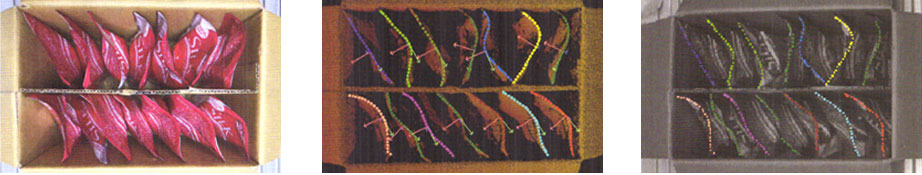

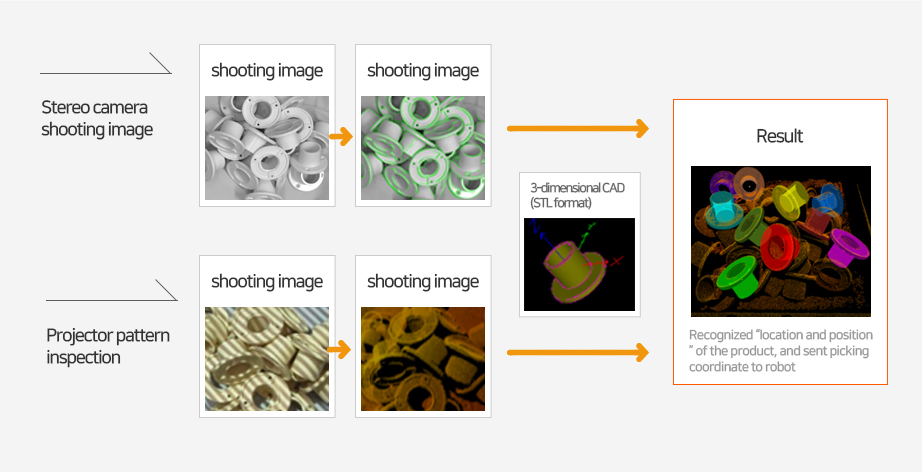

ㆍ 3-dimensional recognition evaluation

and verification for the work

ㆍ Lighting modified for recognition stabilization

ㆍ Parameter setup suitable for requirements

Introduction Effect at Factory Line

ㆍ Input of automotive transmission

parts into process machine

ㆍ No. of workers : 5 persons → 2 persons (Less 3 persons)

ㆍ Dent occurrence rate : 1.7 % → 0 %

ㆍ Production lead time : 60 hrs. → 12 hrs.

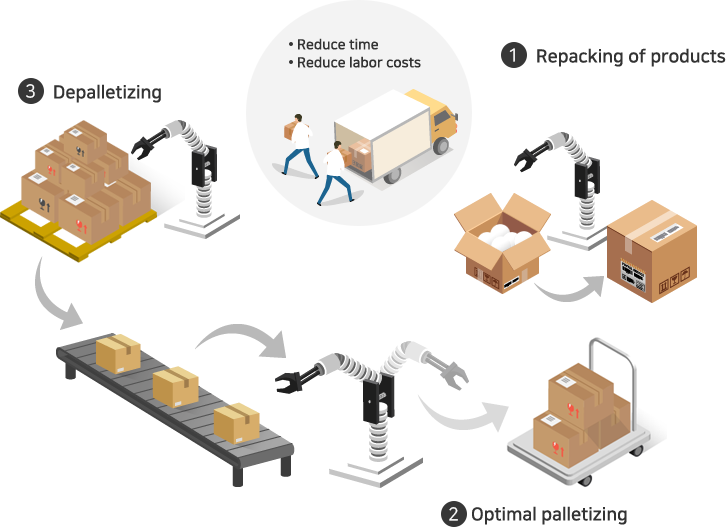

RAMS offers a perfect distribution solution, based on vision and intelligent technology, developed for factory automation

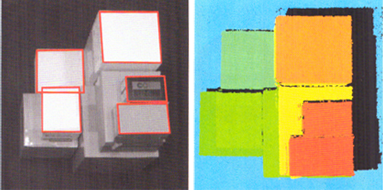

Possible to recognize various boxes simultaneously

Possible to recognize tiny spaces between boxes

IIPR palletizing algorithm offers solutions

like below

- Recognizing as many boxes as possible

- Box packing in minimum distance

- Stacking that prevents box from collapsing

- Flat piling for the maximum result